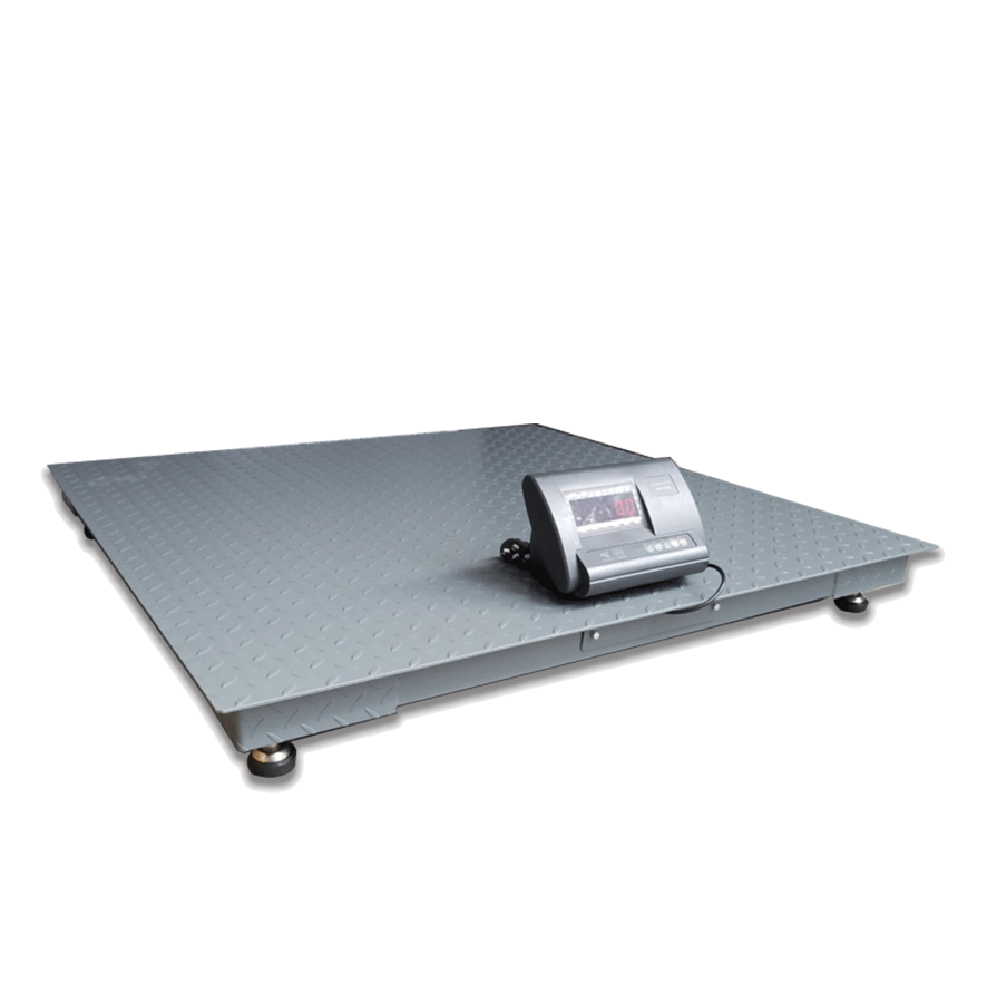

Improve Process Precision with Trusted Industrial Scales Options

Why Industrial Scales Are Important for Maximizing Stockroom Operations

Industrial scales play an essential duty in optimizing storehouse operations by delivering accurate weight measurements that are important for effective stock monitoring and structured shipping procedures. Their capacity to ensure precision not just alleviates problems of overstocking and stockouts however also contributes significantly to waste decrease and expense effectiveness. Additionally, the data generated from these ranges permits educated decision-making, improving resource allocation and functional efficiency. Nevertheless, real impact of commercial scales expands past mere precision-- recognizing their more comprehensive ramifications could change operational strategies in unanticipated methods.

Boosted Precision in Evaluating

In lots of warehouse operations, attaining enhanced accuracy in evaluating is crucial for the general performance and dependability of inventory administration. Exact weighing enables specific tracking of product amounts, which is important for maintaining optimum stock degrees and minimizing waste. Industrial ranges designed for stockroom settings provide high levels of accuracy, thus reducing the margin for error in stock analyses.

Implementing advanced weighing technology, such as digital scales with calibration features, guarantees that weights are regularly precise across different tons. This accuracy is especially crucial when taking care of high-value products or bulk materials, as inconsistencies can cause considerable monetary losses. Exact considering adds to conformity with market guidelines, which typically mandate accurate measurement for safety and security and high quality assurance.

Moreover, boosted considering accuracy makes it possible for far better decision-making relating to logistics and supply chain management. With precise information available, warehouse supervisors can anticipate demand better, plan for replenishment, and optimize storage area usage. Ultimately, the assimilation of precise commercial scales into stockroom operations sustains not just immediate operational demands however additionally long-lasting tactical goals focused on enhancing total efficiency and productivity.

Boosted Inventory Monitoring

Effective stock management is crucial for optimizing stockroom operations and making sure that resources are used successfully. Industrial scales play an essential role in this process by giving accurate weight measurements that straight affect inventory tracking and control. By incorporating these ranges into inventory administration systems, storage facilities can accomplish real-time data accuracy, which is critical for maintaining optimum stock degrees.

The capability to consider items properly enables for far better projecting and replenishment strategies. With exact weight details, warehouse managers can determine inconsistencies in between expected and actual stock levels, therefore reducing overstocking or stockouts. This accuracy additionally assists in categorizing products according to weight, which can improve storage performance and improve order selecting processes.

Additionally, improved stock management cultivates much better vendor connections and customer fulfillment. Exact weight dimensions facilitate compliance with shipping regulations and decrease the probability of expensive errors during the procurement procedure. Basically, commercial scales not only enhance the accuracy of inventory documents yet additionally add to general functional performance, inevitably leading to reduced expenses and enhanced solution distribution in storage facility procedures.

Streamlined Shipping Processes

A significant element of stockroom performance is the streamlining of shipping processes, which can significantly improve general performance and customer fulfillment. Reliable shipping operations make sure that items are dispatched accurately and in a prompt way, directly a fantastic read impacting consumer experience and retention.

Additionally, incorporating commercial ranges right into warehouse administration systems assists in real-time monitoring of stock and deliveries, improving openness throughout the delivery process - Industrial Scales. This integration not just accelerates the fulfillment cycle yet likewise improves interaction among staff, bring about quicker decision-making and fewer bottlenecks

Furthermore, streamlined delivery processes can lower labor expenses, as groups can work extra effectively with clear guidelines and precise data at their fingertips. By embracing industrial ranges, storage facilities can attain a much more organized technique to shipping, inevitably increasing their functional effectiveness and sustaining a stronger profits.

Waste Reduction Approaches

Enhancing warehouse procedures extends past streamlined delivery procedures to encompass waste decrease strategies that dramatically add to general performance and cost-effectiveness (Industrial Scales). Carrying out commercial scales is a crucial aspect of these strategies, making it possible for precise measurement of products and materials, which decreases overages and minimizes excess supply

An additional vital technique is the optimization of product packaging. Industrial scales assist in accurate weight measurements, permitting tailored product packaging remedies that reduce excess products. This not just decreases waste however additionally lowers shipping expenses, as lighter plans typically sustain lower products costs.

Data-Driven Decision Making

Using data produced from commercial scales permits storage facility supervisors to track stock levels extra accurately, causing educated purchasing choices and decreasing overstock or stockouts. This data can be assessed to identify fads in product activity, enabling better projecting and source allotment.

The insights gained from weight data likewise assist in efficiency dimension against essential performance signs (KPIs), such as throughput prices and order accuracy. By using sophisticated analytics, warehouse procedures can discover inadequacies, simplify workflows, and minimize operational costs.

Ultimately, data-driven choice making encourages companies to make positive adjustments, ensuring that storage facility procedures continue to be receptive and active to market needs. Purchasing industrial ranges not only enhances data collection however likewise changes that data right into actionable intelligence, positioning warehouses for continual competition and growth.

Verdict

In summary, industrial scales play a crucial function website link in maximizing storage facility procedures through boosted precision in considering, enhanced stock administration, and structured delivery procedures. These ranges add to waste decrease approaches and facilitate data-driven decision-making, eventually advertising operational effectiveness. By leveraging exact weight dimensions, storehouses can reduce discrepancies, minimize prices, and foster increased consumer fulfillment. The integration of industrial ranges into storehouse monitoring systems is thus vital for attaining optimal performance and source allocation.

Industrial scales play a critical function in enhancing stockroom operations by providing exact weight dimensions that are crucial for efficient supply monitoring and streamlined shipping processes. Industrial scales created for warehouse environments give high levels of precision, thereby decreasing the margin for error in inventory assessments.

In significance, commercial ranges not only enhance the accuracy of supply documents however likewise contribute to overall functional performance, inevitably leading to minimized expenses and enhanced service shipment in storage facility operations.

In summary, industrial scales play a vital duty in maximizing warehouse operations through enhanced accuracy in evaluating, improved stock monitoring, and structured delivery processes. The integration of industrial ranges right into storehouse administration systems is thus critical for accomplishing optimal performance and resource appropriation.